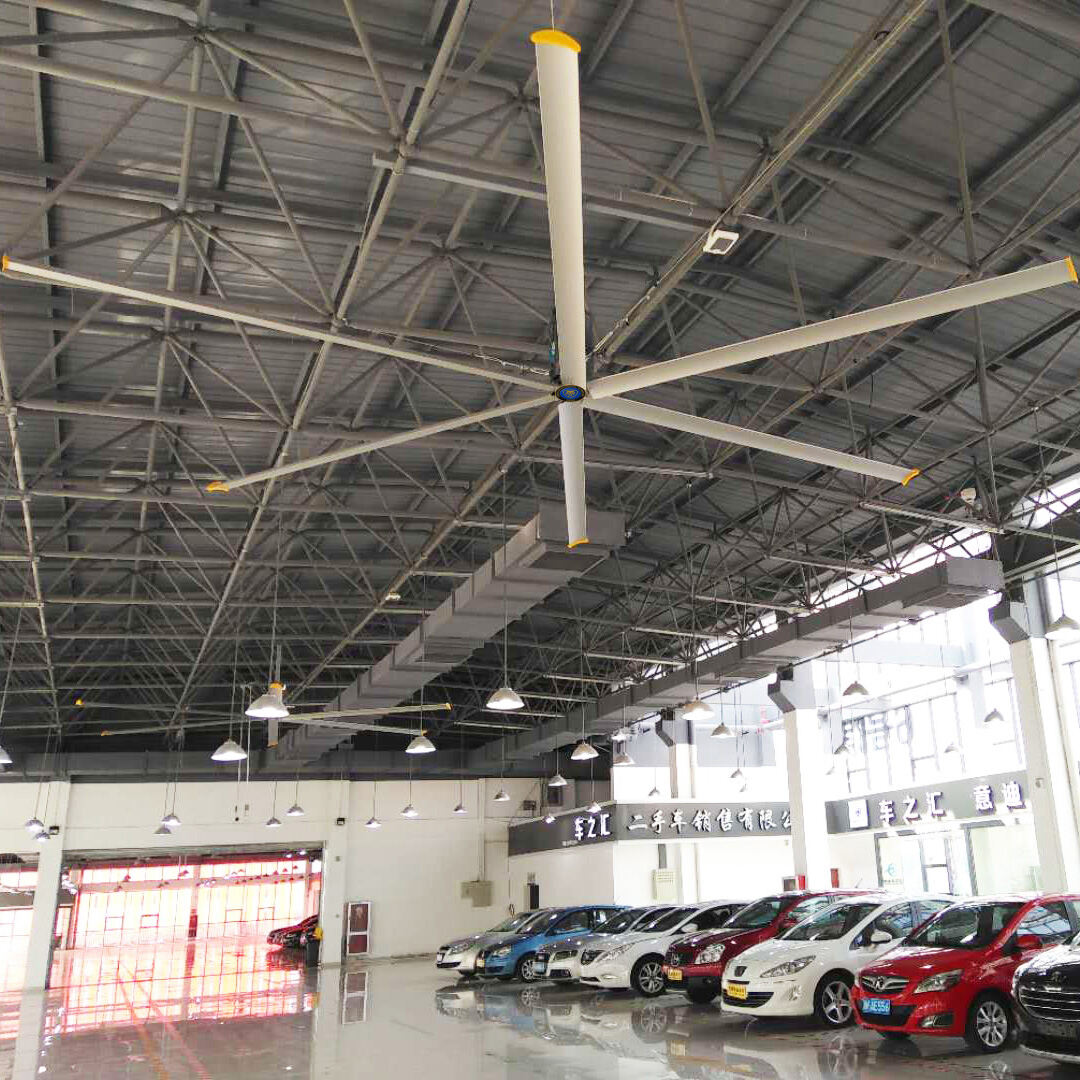

Large HVLS fans for factory workshops

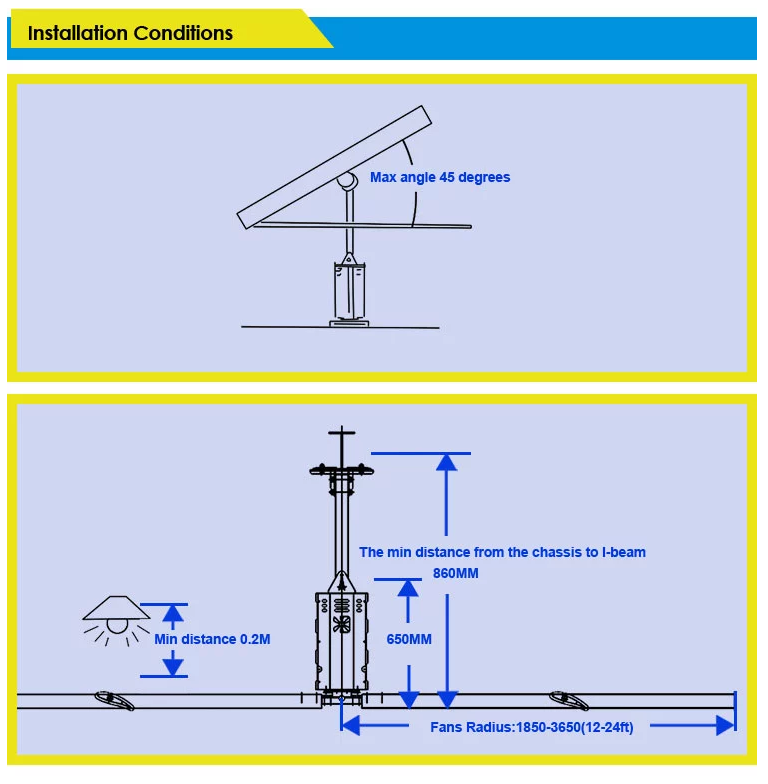

We supply large hvls fans for factory workshops with a diameter 3M up to 7.3M. Just with a power of 1.5KW or less, the blades are able to drive a mass of air and then produce a large scale of natural wind, which leads to the double functions of ventilation and temperature cooling. Compared with the traditional HVAC conditioners and small high-speed air blower, the fan has superior advantages in application, and is the ideal solution to ventilate and cool the air in large area.

- Overview

- Parameter

- Features

- Main Components Tech

- FAQ

- Related Products

Description

We supply large hvls fans for factory workshops with a diameter 3M up to 7.3M. Just with a power of 1.5KW or less, the blades are able to drive a mass of air and then produce a large scale of natural wind, which leads to the double functions of ventilation and temperature cooling. Compared with the traditional HVAC conditioners and small high-speed air blower, the fan has superior advantages in application, and is the ideal solution to ventilate and cool the air in large area.

Parameter

| MODEL |

DIAMETER | NUMBER OF BLADES | AIR VOLUME | WIND COVERAGE | NOISE | SPEED | CONTROL MODE | OVERALL WEIGHT | POWER | VOLTAGE |

| DN-FQ-73E-6 | 7.3m | 6 | 18000m³/min | within diameter 30m area |

≤60db | 20-52rpm | Frequency Control |

130KG | 1500W | 220V/380V |

| DN-FQ-73G-6 | 7.3m | 6 | 18000m³/min | within diameter 30m area |

≤60db | 20-52rpm | Frequency Control |

130KG | 1500W | 220V/380V |

| DN-FQ-73E-8 | 7.3m | 8 | 18500m³/min | within diameter 30m area |

≤60db | 20-52rpm | Frequency Control |

140KG | 1500W | 220V/380V |

| DN-FQ-73G-8 | 7.3m | 8 | 18500m³/min | within diameter 30m area |

≤60db | 20-52rpm | Frequency Control |

140KG | 1500W | 220V/380V |

Advantage

1. Large coverage,low noise

2.Excellent comfort, people can feel 5℃-8℃ temperature reduction

3. Energy saving,the max power is only 1.5kw

Main Components Tech

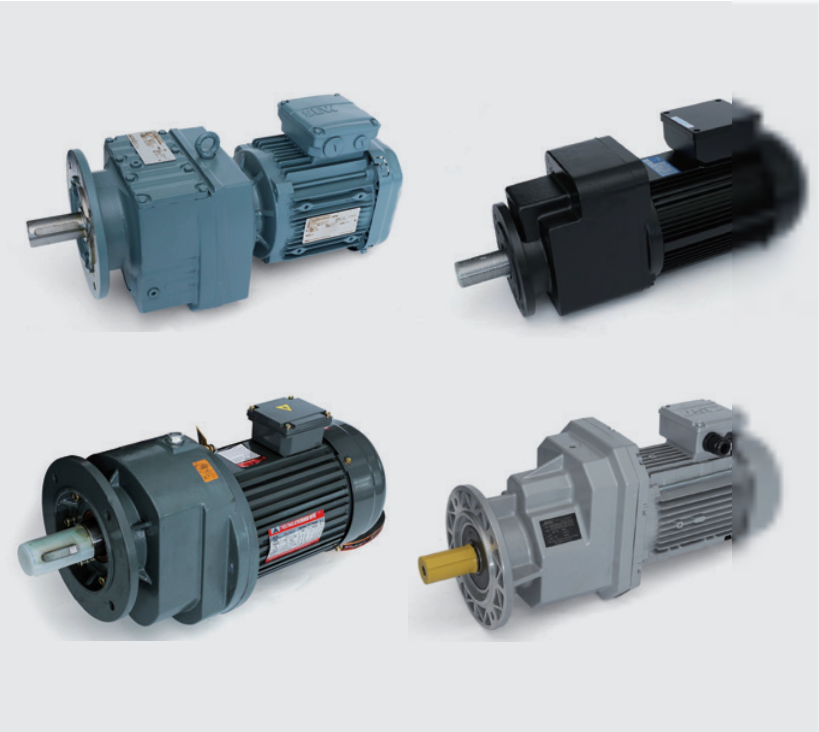

Motor system

Compared with common geared motor

Adopt imported Germany LENZE motor, and work with Germany company to develop geared motor for HVLS products.

1. Use low backlash assembly process and gear grinding technique, lower noise

2. Strength the bearing frame structure, increase oil seal and strength the motor structure with trapezoidal shaft structure, higher safety

3. Adopt IE2 high efficient motor, save more 5-10% than IE1

4. Passed CCC, CE, UL certificates

Hub

The die-casting high-strength aluminum alloy material is used to effectively prevent the pores and burrs and prevent the root fracture risk. The machining center is used for one-time forming, the impact resistance is stronger, and the accidental rigid collision will not break.

Control system

Schneider brand electrical sets, with buildin safety protection module which will shut down the output automatically in case of some accidents.

Germany brand control cabinet, passed EMC by SGS and CCC certificates, minus, passed anti-creeping tests which shields electromagnetic interference effectively.

Fan Blade

Adopt imported special high strength aviation magnesium-aluminum alloy, surface oxidation treatment,and aerodynamics fan blade design.There is strengthening support system inside,which increases the strength of fan blade and avoids the drop of fan blade tail and the loss and fatigue of fan blade to connecting pieces completely.

Winglet

Aerodynamics Winglet

Aerodynamic tail fins are often seen on airplanes and racing cars, but they are not not designed for beauty。Eddies will be formed in the end of the streamlined fan blade while airflow is running. With winglet, this part of energy loss will be avoided,fan will run steadily, which will bring economic effect.

FAQ

Q: Are you the factory?

A: Of course, we are a factory focusing on large ceiling fans based in Shanghai, China, be your direct fan supplier.

Q Where does your fan use in?

A: Ths fan is widely used in factory, logistics & warehouse, supermarket, halls etc.

Q: Is it used in electrcity?

A: Yes, it's power supply is electricity, but only 1.8KW or less, very energy-saving.

Q: What the price per fan?

A: We will offer you the best price according to the qty and the model.

Q: How long is the delivery time?

A: Normally 3-5 working days.

Q: How long is the warranty?

A: We offer 2-year warranty to guarantee the quality. Most importantly, its service life is 12-15 years.

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES SV

SV CA

CA TL

TL IW

IW ID

ID LV

LV UK

UK VI

VI TH

TH TR

TR AF

AF MS

MS GA

GA UR

UR BN

BN KM

KM LO

LO MN

MN TA

TA MY

MY